Message from Managing Director, Mr David Wong,

SMC Corporation (Singapore) Pte. Ltd.

I trust this message finds you in good health and unwavering resilience. Reflecting on the year 2023, it was characterized by the recovery phase from the Post Covid-19 pandemic, introducing unforeseen challenges and disruptions to the supply chain, compounded by a global economic slowdown.

As we embark on the journey into 2024, the global economic landscape continues to grapple with uncertainties stemming from global inflation, geopolitical conflicts, escalating energy and food costs, and concerns about job displacement. Despite these formidable challenges, there exist pockets of opportunities for exploration and strategic capitalization.

The paradigm shift towards Industry 5.0, integrating technologies such as IoT, AI, 5G, and big data analytics, is propelling the demand for industrial automation. Recognizing the imperative to enhance efficiency, optimize production, and maintain competitiveness, manufacturers are increasingly adopting industrial automation technologies.

Addressing challenges such as high labour costs and workforce shortages, the manufacturing sector is embracing industrial automation to further streamline operations, reduce labour dependency, and elevate productivity.

Advancements in robotics, digitalization, 5G, and generative AI are unlocking unprecedented opportunities in industrial automation. Collaborative robots (Cobots) are gaining prominence, facilitating safe human-robot collaboration. Energy efficiency takes center stage, and SMC is well-positioned to provide solutions such as the 4 Bar-concept and SMC Air Management System as well as its Digital Architecture, optimizing air consumption and digitalization of processes to meet ecological goals.

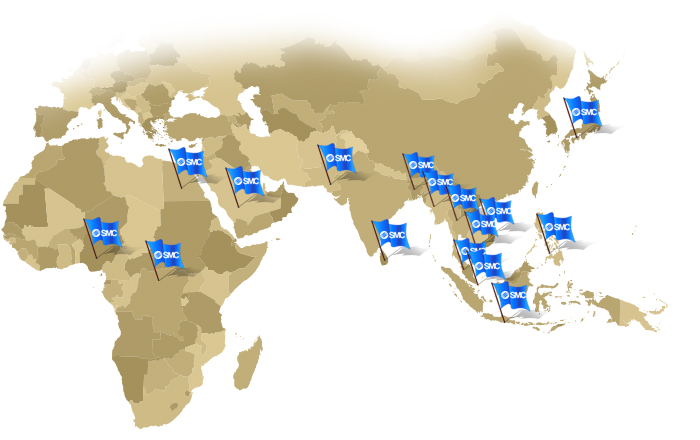

Aligning corporate values with sustainability goals and maintaining a robust Business Continuity Plan (BCP) remain pivotal differentiators for SMC. A commitment to one-stop-shop customer service & support, supplier collaboration, and resilient supply chain management remains at the forefront of SMC’s priorities.

SMC Corporation has diligently established robust business continuity plans, strategically minimized disruptions, and ensured a resilient product stock supply. The formation of the SMC GRC (Governance, Risk, and Compliance) team enhances communication and information sharing, fortifying our ability to anticipate potential disruptions and safeguard our operations.

In conclusion, while this year has presented its share of challenges, we remain resilient and optimistic. On behalf of SMC, I extend heartfelt wishes for the safety, health, and positivity of all our stakeholders. Let us remain resilient and focused as we strive for even more successful years ahead.

Updated in April 2024